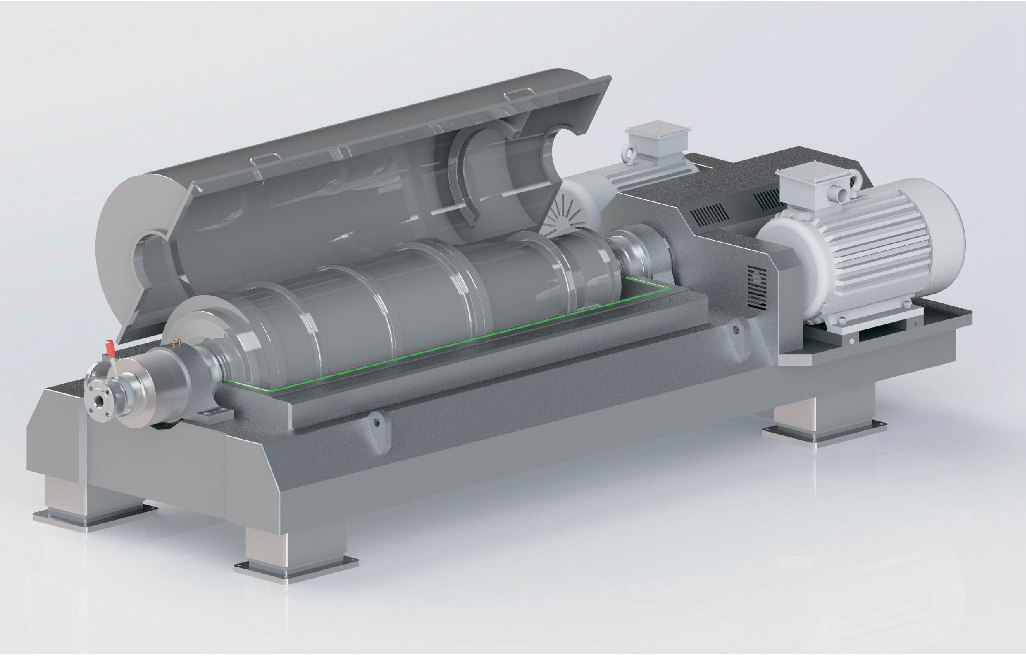

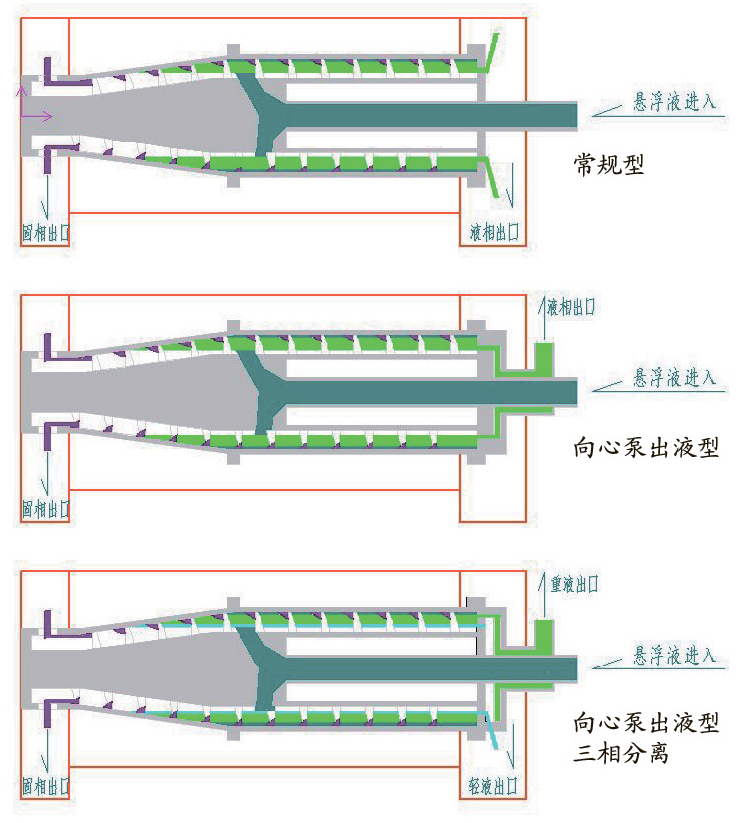

工作原理

悬浮液通过进料管进入转鼓内,在离心力场作用下密度较大的固相沉降至转鼓壁上,固相在螺旋的推动下从沉降区至干燥区后从出渣口排出;澄清的液相从转鼓大端溢流口溢出,实现固液分离。

LWS为三相分离型。

Operating principle

Once the suspension fed into the centrifuge drum via feed pipe, solid phase of it of higher density will be settled down and attached to wall surface of the rotor drum under effect of centrifuge field. which will be screw pushed to drying area before it's discharged via slag outlet,the clarified Iiquid phase of it will be overflowed via the overflow port of the rotor drum,hence to realize solid and liquid separation.

LWS is three-phase separation type.

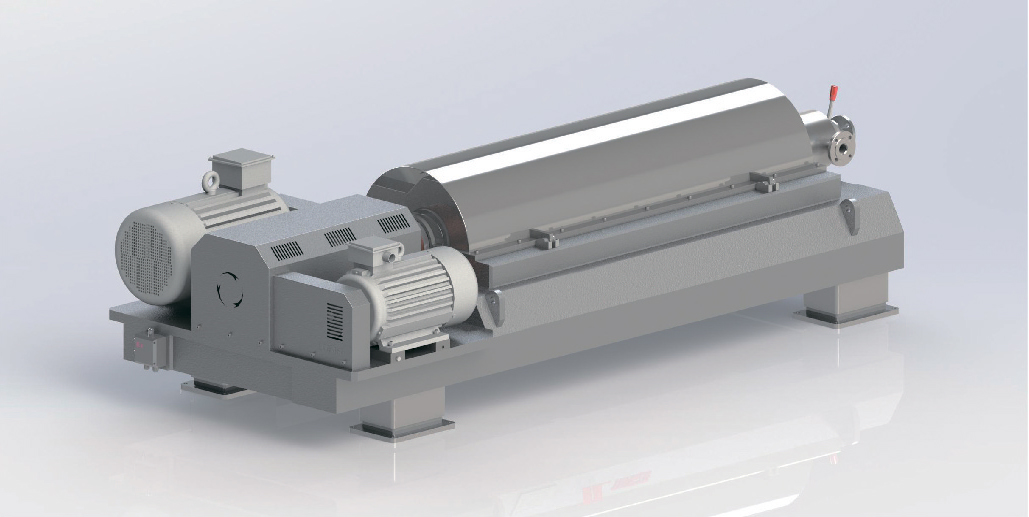

LWS外形图 LWS Outline drawing

主要特性

u 转鼓、螺旋等与物料接触部分材料按使用工况选择相应的耐蚀不锈钢、双相钢或C22

u 高精度转鼓(数控加工、高精度平衡),高分离因数,提高分离效率

u 双变频共直流母线控制,转鼓、螺旋转速无级调整

u 多种润滑方式:脂润滑(标配)、喷油润滑、油气润滑

u 全自动加油装置

u 螺旋叶片表面喷涂耐磨合金或镶焊硬质合金

u 对应不同的工况,选择适合的差速器:摆线针轮、行星齿轮或液压差速器

u 系统全密闭,满足清洁生产要求

u 多重保护:过振动保护,开盖保护,电机过载保护,差速/转矩控制切换,轴承温度检测,螺旋推料扭矩保护,静电接地保护,检修锁定保护

u 配置氮气保护系统以及相应的防爆措施,满足防爆要求

u 可集合絮凝剂加药系统、螺杆泵、流量计等,组成全套污水处理系统

Main features

Components/parts including drum and screw etc that will be in contact with the feedstock are made of corrosion resistant stainless steel,duplex steel or C22 according to the working condition.

u High precision rotary drum(NC machining,high-precision balance),high separation factor, improved separation efficieney.

u Dual variable frequency common DC bus control, step-less velocity adjustment of drum and screw;

u A variety of lubrication methods: grease lubrication (standard),oil injection lubrication,oil and gas Iubrication.

u Fully automatic oil recharging device

u Surface of the spiral vane is sprayed with wear-resistant alloy or welding hard alloy.

u Different differential mechanism is equipped for different working conditions,i.e. cycloid pin, planet gear or hydraulic differential.

u Fully enclosed system satisfying specification of pharma production

u Multiple layers of protection including over-vibration protection,cover opening protection,motor overload protection,differential speed/torque control and switch, bearing temperature detection,screw pushing torque protection,static grounding protection and Iocking protection for maintenance

u N2 protection system and relevant ex-proof measures are equipped to satisfying ex-proof specification

u Can be core part of a waste water treatment system once combined with flocculant dosing system, screw pump, flow meter and other fittings

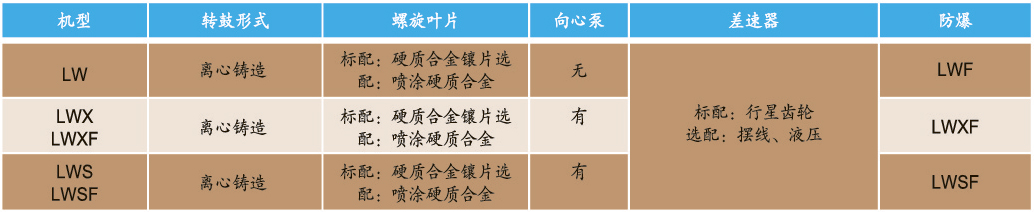

定制形式 Personal form

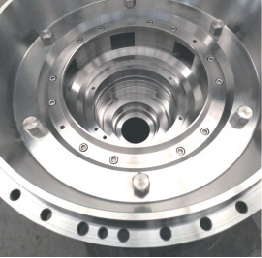

转鼓离心铸造

u 转鼓整体离心铸造、固熔处理,比较好的稳定性

u 更高的强度

u 多种材质304、316L、2205、C22、C276

Centrifuga casting of rotor drum

u The rotor drum is made by means of centrifugal casting and solution treatment,which means better stability

u Higher strength

u Can be made of various material including 304、316L、2205、C22、C276

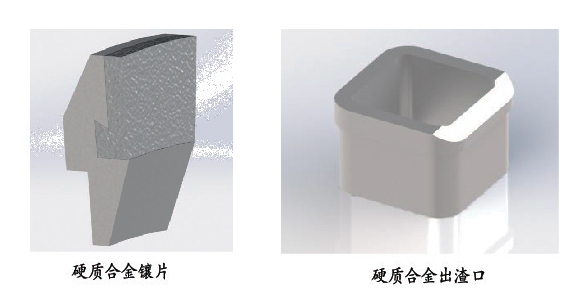

螺旋耐磨处理

u 硬质合金镶片

碳化钨合金

镶嵌结构

u 表面硬质合金喷涂

推料面碳化钨合金喷涂

Screw wear-resistance treatment

u Cemented carbide insert

Tungsten carbide alloy

Built-in structure

u Cemonted carbide coated surface

Tungsten carbide coated

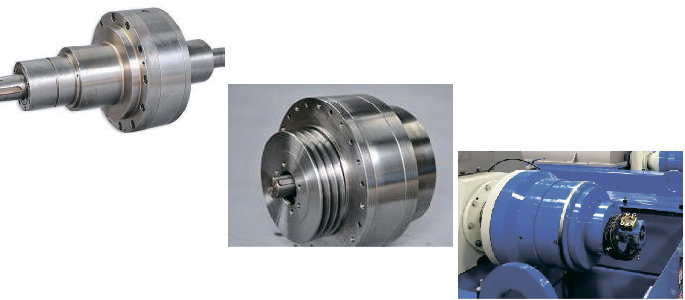

差速器

u 摆线针轮差速器

u 行星齿轮差速器

较大的扭矩输出

运行稳定可靠

u 液压差速器

较好的低差速输出

差速无级可调

紧凑的结构

Differential mechanism

u Cycloid pin wheel differential

u Pianetary gear differential

Larger torque output

Stable and reliable operation

u Hydraulic differential mechanism

Better Iow differential output

Differential stepless adjustable

Compact structure

密闭性能

u 轴封设计

确保工作腔与轴承腔之间有效隔离

u 出渣柔性接口与输送接口

按安装设计可以选配柔性接口或输送接口

Sealing performance

u Shaft seal design

ensuring effective separation between the working cavity and bearing cavity

u Flexible joint for slag discharge and transfer connection

Flexible joint or transfer connection for option of installation design

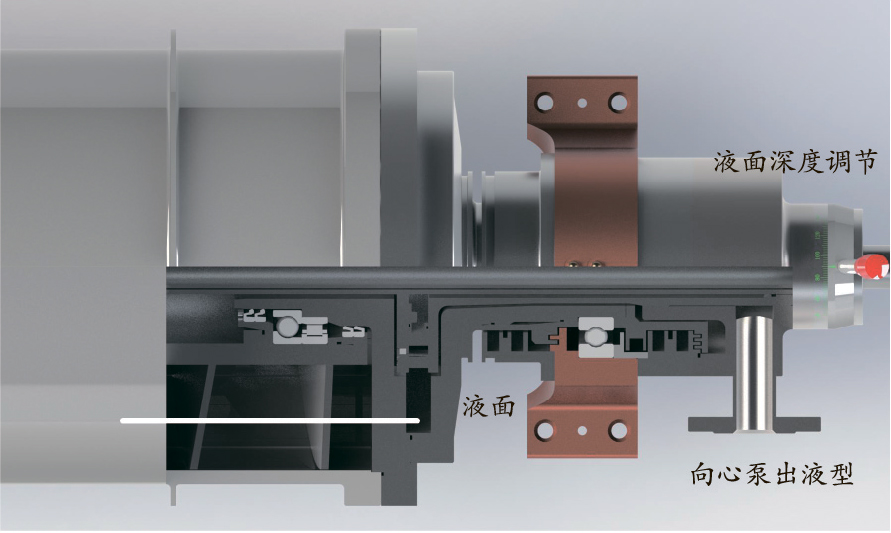

向心泵出液

u 液相通过向心泵抽出,液位可按工艺要求设定

u 整机密闭性好

Liquid phase to be discharged by centripetal-pump

u Liquid phase will be discharged by centripetal pump,with liquid level programmable as per process requirements

u Good sealing performance of the whole system

三相分离

u 应用于固-液-液分离

u 较重液相向心泵抽出(液面可调)

u 较轻液相转鼓溢流口溢出(液面可调)

Three-phase sparation

u Applicable for solid-Iiquid-liquid separation

u Heavier Iiquid to be discharged by centripetal pump (Liquid level adjustable)

u Lighter Iiquid to be overflowed via overflow port of the rotor drum (liquid level adjustable)

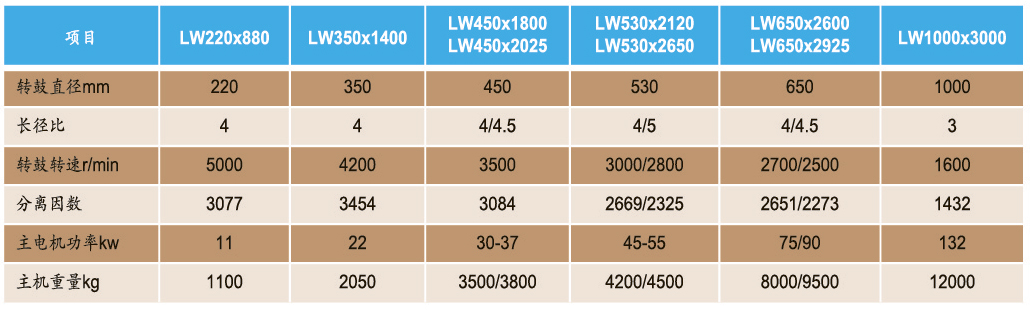

技术参数 Technical parameter

u LWS技术参数同上表

u 长径比上表中为常规参数,可按实际工况进行调整,以达到较为理想的分离效果

u Please refer to the Table above for technical parameters for LWS

u Ratio of length to diameter shown in above Table are generic parameter,which is subject to adjustment base on working conditions in order to achieve satisfying performance of separation.

防爆与密闭

u 整机密闭

u 轴封设计

u 氮气保护系统

u 出渣口接口

u 防爆/隔爆措施

(详见防爆技术应用)

Explosion-proof and sealing

u Sealing of the whole system

u Shaft seal design

u N2 protection system

u Slag discharge connection/joint

u Explosion proof and separation measures

(Refer to Application of Ex-proof Technology for detail)