For the centrifuge to be used in space involving ex-proof requirements, the user shall select and order proper type/model of centrifuge depending on ex-proof configuration and measures so specified based on features of separation medium as well as its physical and chemical properties including corrosive medium and its concentration, temperature and other factors (e.g. impurity, PH value, with or without air, flowing or static

Meeting ex-proof requirements (and satisfying anti-corrosion specification) is the thing of first priority to consider while selecting the centrifuge of right model/type!

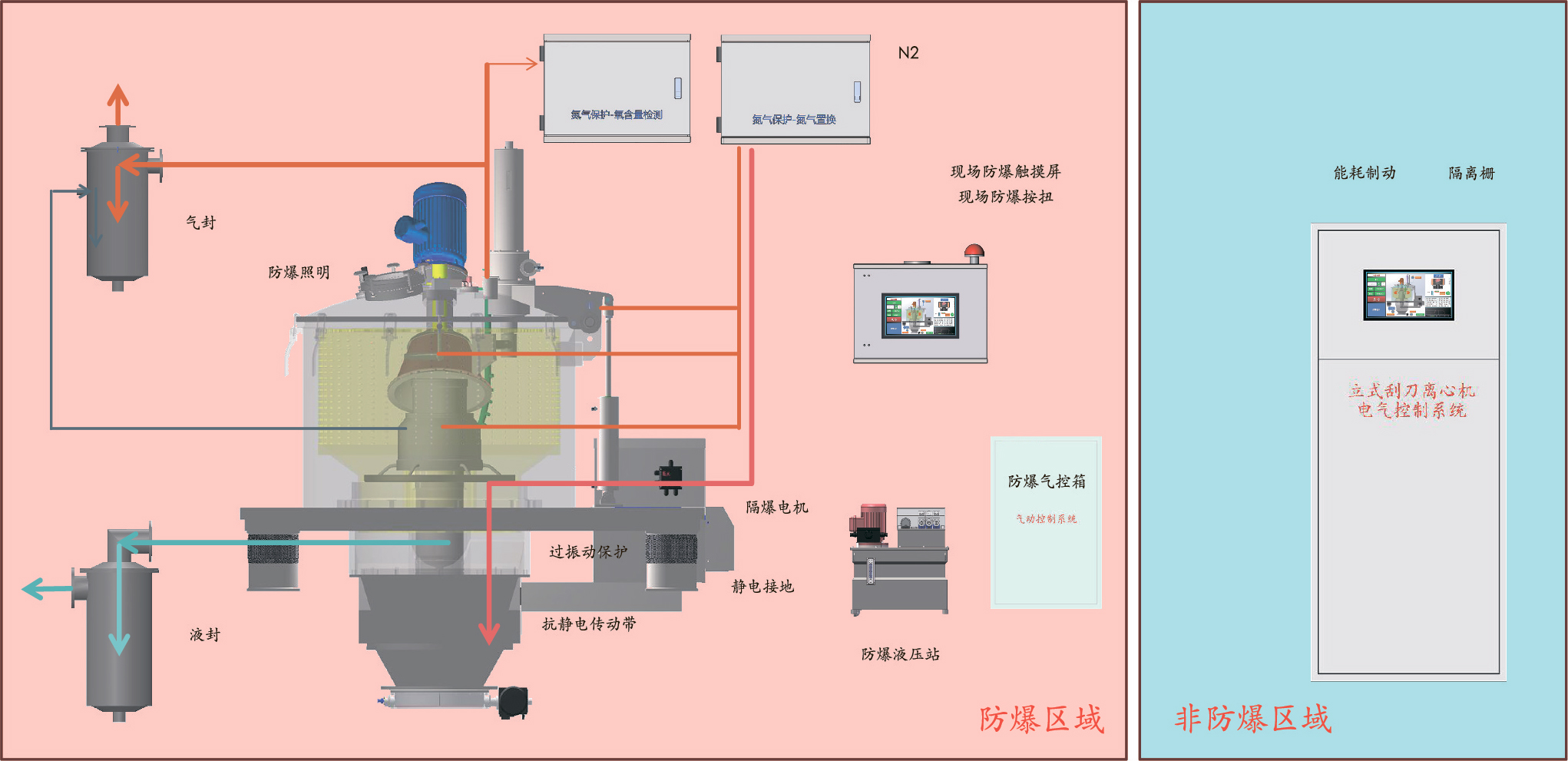

- To obtain medium properties and ex-proof requirements

- To calculate safe range of oxygen content

- To propose ex-proof configuration

- Volumeric displacement (high efficient convection displacement)

- Flow detection and volume control

- Oxygen content detection and control

- Sampling air condensate removal and active carbon filtering

- Oxygen content detection

- Inner cavity micro-pressure protection

- Main shaft sealing, scrapper shaft seal, distributor shaft seal: Shaft seal pressure is 20mbar higher than that of the inner cavity, organized venting of the shaft seal.