The centrifuge is mainly applied in field of nonorganic chemical, organic chemical, petroleum,pharmaceutical and intermediates, chemical fertilizer, farm chemical,dye, food and additives. With its centrifugal force, the powerful filtering pressure, the centrifuge is applicable for separation of solid/liquid mixture and purifying(rinsing)products out of the separation process and therefore widely applied in many industries.

Whether a centrifuge is applicable is determined by following factors:

1) Type of separation to be undertaken, liquid or solid(medium corrosive or explosion-proof?)

2) Size, shape and density of particles(size distribution)

3) Density of the solid content and relative density of the liquid content

4) Sedimentation rate

5) Sedimentation rate

6) Dynamic viscosity

7) Temperature

8) PH value

9) Throughput

10) Washing requirement

11) GMP requirement

...

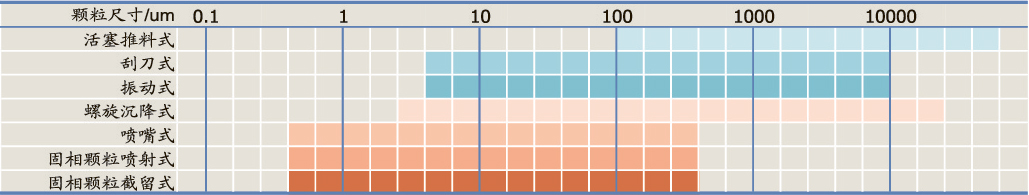

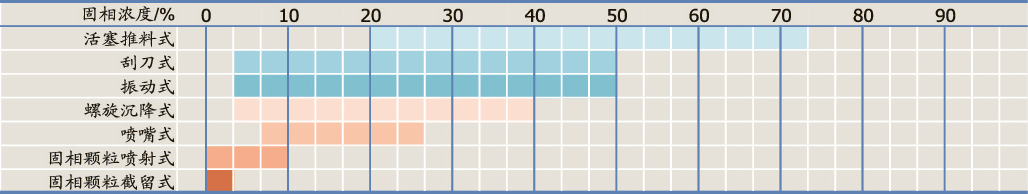

Among which,size of solid particle,sedimentation rate and concentration of the mixture are three major index for determining applicability/serviceability of the unit.In addition to physical and chemical properties abovementioned,factors/index including washing requirement, solid content rate of the Iiquid phase, moisture content of the filtering cake and other factors also need to be considered while determining application/serviceability of the unit.

To define a most applicable separation process, the most suitable technoIogy to be applied shall be selected from three options, i.e.filtration, sedimentation or sedimentation plus filtration. Sedimentation option is more economic than the filtration option and it’s especially suitable in case of bulk amount of treatment and continuous flow of liquid.

Selection of filtering

Filtration medium, which could be any permeable material that retains solid particle on its surface or inside of it in filtration process, determines effectiveness and validity of filtration process.

Main function of the filtration medium is to separate the solid particles out from the flowing Iiquid by consuming minimum energy.

Effective filtration, to a Iarge extent,depends on proper selection of applicable filtration medium, the customer may refer to those technical specification and information as results of research efforts and experience of the industry concerning performance and selection of filtration medium, however, to select the filtration medium, relevant experiments and tests shall be conducted to the solid and liquid mixture to be separated extremely carefully as a tiny change in process of experiments/tests might bring major impact to the results.

Diversity of the fiItration medium makes it a hard job to select the proper applicable one, you can hardly define which filtration medium is the most applicable for the specific separation operation simply by referring to its particle size and size distribution, in fact, change of partiele coneentration and shapes will make your decision of filtration medium harder.

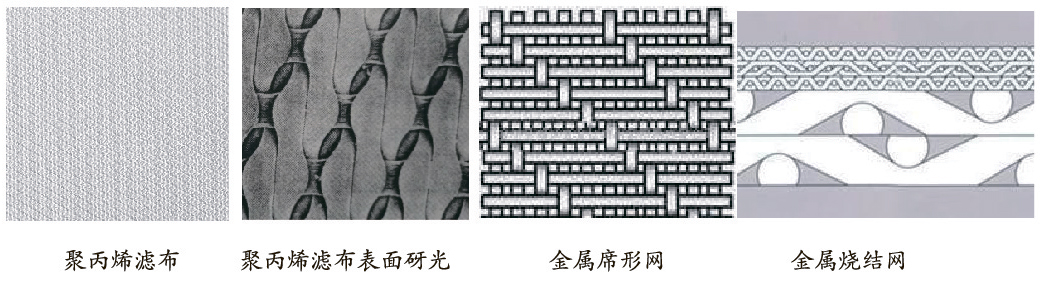

Woven filter cloth and non一woven filter cloth made of polymeric material: Polypropylene,polyethylene, polyester, polyamide, polyvinyl chloride and others.

Single wire double-layer composite filter eloth:It’s a double-layer filtering medium, with satin weave texture on smooth surface of the top layer,such smooth surface may bo subject to matting treatment for improvement. The bottom Iayer is made of single wire woven cloth of higher strength which is supportive and helpful for discharging. Particles penetrating or passing through the top layer would not be retained there resulting in clogging, instead, it will flow down along the funnel in between the top Iayer and bottom supportive layer, which is good for regeneration of filtering cloth.

Metal net or mat sheet could be selected as filtering medium for large particle solid to achieve higher filtering efficiency.